Sintering Calcium Aluminate

Sintered Calcium Aluminate(Synthetic slag) produced by rotary kiln.Calcium aluminate is mainly used for separating the impurity elements such as sulfur and oxygen in ladle refining of LF furnace, open hearth furnace and the converter furnace, and it can reduce the content of harmful elements and impurities, which is applicable for general carbon steel, high carbon steel, high and low alloy steel. Its applications have already been mature in some foreign countries, such as South Korea, Japan, the United States and the developed European countries.

APPLICATIONS

- A key feature for successful ladle metallurgy is slag control. Calcium Aluminate is specifically designed to have the required chemical composition and physical properties that make it easy to store and handle.

- Calcium Aluminate is hard, stable and nearly dust-free.

- The Calcium Aluminatehas good sulphur retention and performs effectively as a desulpheric slag.

- Calcium Aluminate contains no fluorine compounds, thus avoiding refractory attack and atmospheric pollution. Calcium Aluminate is the best substitute for Calcium Fluoride.

- Calcium Aluminate is an excellent cover slag for the prevention of gaseous pick-up from the atmosphere and is an effective fluid sink that absorbs inclusions from steel.

ADVANTAGES OF CALCIUM ALUMINATE

- Consistent chemistry

- Superior refractory protection

- Readily available

- Sized and packaged to customer specification

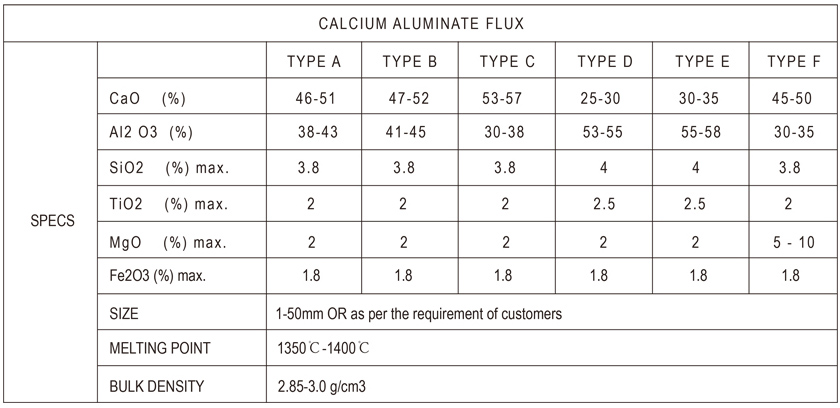

SPECIFICATIONS

Contact Us

Location:

21 Bis rue du Simplon

75018 - Paris

France

Email:

sales@alphametals.fr

Call:

+33954653328, +33695057331